stud and track roll forming machine is a type of roll forming equipment that transforms flat metal coils (typically made of steel or aluminum) into specific cross-sectional shapes through a continuous bending process. It is designed to produce two main products:

Product version

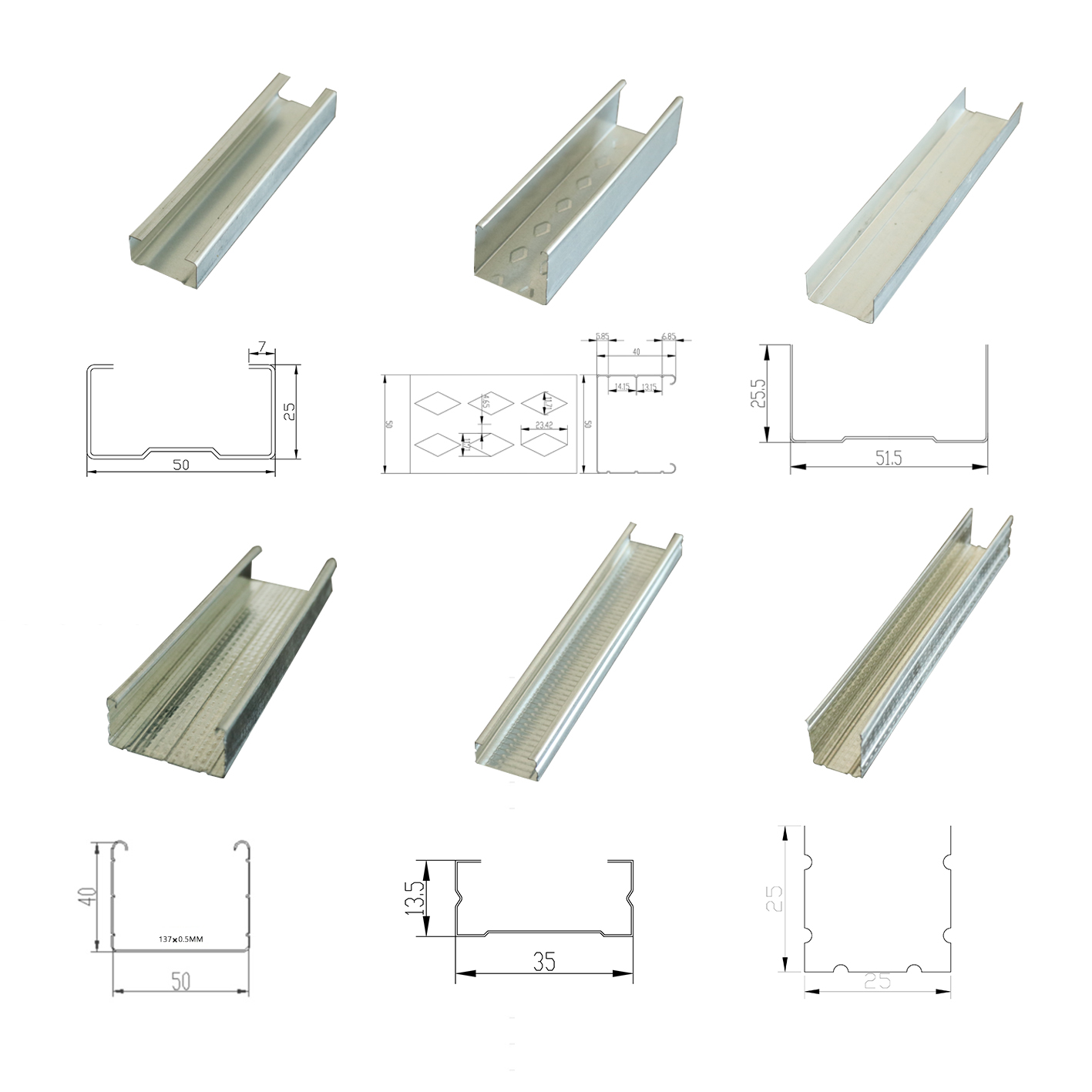

The above pattern diagrams include: CU ALL-IN-ONE MACHINE - U-SHAPED

Advantages

1. High production efficiency and continuous molding capability

- By adopting a multi-station rolling forming process, metal sheets are gradually bent into the required shape through a series of precisely designed rollers. - With a high degree of automation, it can integrate functions such as uncoiling, leveling, punching, and fixed-length cutting, achieving fully automatic continuous production and reducing manual intervention.

2. High precision and consistency

Through PLC or CNC control systems, the dimensional tolerance of the profiles is ensured to be within ±1mm, meeting the strict assembly requirements of the building frame.

The rollers are made of Cr12 or Cr12MoV high-hardness tool steel, which is highly wear-resistant and can maintain high precision even after long-term use.

3. Strong material adaptability

It can process galvanized steel (GI), cold-rolled steel (CRC), and hot-rolled steel (HRC), with a thickness range typically from 0.3 to 1.5mm, meeting the requirements of different construction standards.

By changing the roller molds, the production of C-shaped/U-shaped profiles of different sizes can be quickly adjusted to meet the diverse project requirements.

4. Energy conservation, environmental protection and low cost

Compared with traditional welding or forging processes, roll forming generates no waste materials (such as stamping scraps), and has a high material utilization rate.

Electrically driven, with low energy consumption and no welding fume or noise pollution, it conforms to the modern green manufacturing trend.

5. Structural stability and durability

The formed steel keel has a high strength-to-weight ratio, is resistant to corrosion and insect damage, and is non-combustible, which is superior to wooden frames.

The machine adopts a high-rigidity frame (such as a welded steel plate structure) and servo/hydraulic drive to ensure long-term stable operation.

6. Flexibility and expansion capabilities

Optional functions such as online punching, corner cutting, and flying shears can be equipped to achieve one-stop production and reduce subsequent processing steps.

Some models support quick mold changing, meeting the demands of small-batch customized production.

7. Reduce labor and operational costs

Automated production reduces reliance on skilled workers and enhances workshop efficiency.

Company Profile

Cangzhou Huanuo Founded in 2006, we specialize in designing and manufacturing high-quality cold-bending equipment. Our 15,000㎡ facility integrates R&D, production, and sales, offering a wide range of machines including forming machines for roofing tiles, C/Z steel, guardrails, light steel villas, and customized solutions.